An internal combustion engine looks complicated because it is.

But at its core, it does one simple job: turn fuel into motion.

That motion starts as tiny explosions inside metal cylinders and ends with your wheels turning down the road. Between those two points are dozens of components working in precise coordination. Miss one, mistime one, or starve one of oil or coolant—and the whole system fails.

To understand an engine properly, it helps to stop thinking of it as a single machine and instead see it as six interconnected systems. Each system has a clear role, and together they form one continuous mechanical process.

Let’s break it down.

The Basic Engine Cycle (The Foundation)

Every gasoline engine operates on the same four-step cycle:

- Intake – air and fuel enter the cylinder

- Compression – the mixture is compressed

- Combustion – a spark ignites the mixture

- Exhaust – burned gases are expelled

That cycle repeats thousands of times per minute in each cylinder. The parts you’ll read about below exist to make that process controlled, timed, cooled, lubricated, and repeatable.

System 1: The Rotating Assembly

At the heart of the engine is the rotating assembly. This is the system that physically converts combustion into rotation.

Pistons and Connecting Rods

A piston moves up and down inside a cylinder. It is connected to a connecting rod via a wrist pin. The bottom of the rod attaches to the crankshaft.

As combustion pushes the piston downward, the connecting rod transfers that force to the crankshaft.

Crankshaft and Bearings

The crankshaft converts the piston’s up-and-down motion into rotational motion. It spins continuously as the engine runs.

Bearings sit between:

- the crankshaft and the engine block

- the crankshaft and connecting rods

These bearings reduce friction and prevent metal-to-metal contact. Thrust bearings control forward-and-back movement of the crankshaft.

This entire assembly is housed inside the engine block.

System 2: The Engine Block and Sealing

The engine block is the structural foundation of the engine. It forms:

- the cylinder walls

- oil passages

- coolant passages

Piston Rings

Each piston uses three rings:

- Two compression rings seal the combustion chamber

- One oil control ring spreads a thin oil film on the cylinder wall

This seal is critical. Without it:

- compression escapes

- oil burns

- power drops

- engines fail

Oil and coolant galleries inside the block circulate fluids that keep everything alive.

System 3: Lubrication (Keeping Metal Alive)

Engines destroy themselves quickly without oil.

Oil Pump and Oil Pan

Oil sits in the oil pan (also called the sump). An oil pickup tube draws oil into the oil pump, which is driven by the crankshaft.

The pump pressurizes oil and sends it through the engine’s galleries.

Oil Filter

Before oil reaches critical components, it passes through the oil filter, which removes contaminants that would otherwise cause wear.

Seals

- Front main seal prevents oil leaks at the crank pulley

- Rear main seal prevents leaks at the back of the engine

Together, the lubrication system ensures every moving part rides on a protective film instead of grinding itself apart.

System 4: The Cylinder Head and Valvetrain (Controlling Airflow)

The cylinder head bolts to the top of the engine block and seals the combustion chambers using a head gasket.

This is where airflow is controlled.

Valves

Each cylinder uses:

- Intake valves to let air in

- Exhaust valves to let gases out

Valves are held closed by valve springs, secured by valve spring retainers.

Camshaft and Rocker Arms

The camshaft rotates in sync with the crankshaft. Its lobes push on rocker arms, which open the valves at precisely the right time.

Oil lubricates this assembly, and valve stem seals prevent oil from leaking into the combustion chamber.

This system determines when air enters and exits the engine—timing here is everything.

System 5: Timing (Keeping Everything in Sync)

An engine only works if:

- pistons move at the right time

- valves open at the right time

- sparks fire at the right time

Timing Belt and Gears

The crankshaft gear drives the camshaft gear via a timing belt.

The belt also often drives:

- the water pump

A timing belt tensioner keeps the belt tight so it doesn’t skip teeth.

Covers

Timing covers protect the belt from dirt and debris.

A valve cover seals the top of the engine.

If timing fails, valves can collide with pistons—often destroying the engine instantly.

System 6: Cooling (Preventing Overheating)

Engines generate enormous heat.

Water Pump

Driven by the timing belt, the water pump circulates coolant through the engine block and head.

Thermostat

The thermostat controls coolant flow:

- Closed when cold (engine warms up faster)

- Open when hot (coolant flows to radiator)

Radiator and Fan

Hot coolant flows to the radiator, where heat dissipates into the air. A cooling fan assists when airflow is low.

Radiator Cap and Reservoir

Coolant expands as it heats. The radiator cap manages pressure and allows excess coolant to move into a reservoir.

System 7: Air Intake and Exhaust (Breathing In and Out)

Intake Side

Air enters through:

- Air filter – removes contaminants

- Intake pipe

- Throttle body – controls airflow via a butterfly valve

- Intake manifold – distributes air to each cylinder

An idle air control valve fine-tunes airflow at idle for smooth operation.

Exhaust Side

After combustion:

- gases exit through the exhaust manifold

- pass into the catalytic converter

- flow through the muffler

- exit the tailpipe

The catalytic converter reduces harmful emissions before they leave the car.

System 8: Ignition and Electrical

Spark System

A spark plug ignites the air-fuel mixture.

Because 12 volts isn’t enough, an ignition coil boosts voltage to tens of thousands of volts.

In distributor-based systems:

- the distributor routes spark to the correct cylinder

- the rotor spins in sync with the camshaft

- spark plug wires deliver energy

Alternator

The alternator generates electricity while the engine runs, keeping the battery charged.

It’s driven by a belt connected to a harmonic balancer, which also dampens vibrations in the rotating assembly.

System 9: Fueling

Fuel starts in the fuel tank.

A fuel pump sends it through:

- a fuel filter

- fuel lines

- into the fuel rail

A fuel pressure regulator maintains correct pressure.

Fuel Injectors

Each fuel injector sprays a precise amount of fuel into the engine at the right moment, controlled by the ECU.

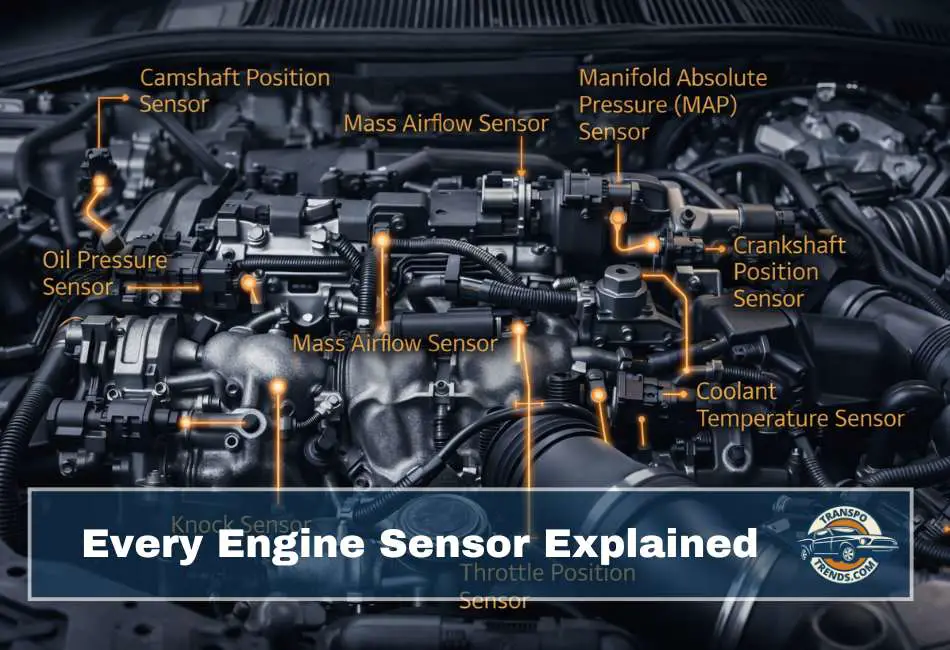

System 10: Engine Management

The ECU (Engine Control Unit) monitors and controls nearly everything.

Sensors

Key sensors include:

- crankshaft position

- camshaft position

- throttle position

- coolant temperature

- intake air temperature

- oxygen sensor

- manifold pressure (MAP)

These sensors feed data to the ECU, which adjusts:

- fuel delivery

- ignition timing

- idle speed

- emissions control

All components communicate through the wiring harness.

The Big Picture

An engine is not magic.

It is controlled chaos.

Fuel explodes.

Metal moves.

Heat builds.

Fluids circulate.

Electronics coordinate.

Every part exists to keep that process balanced.

Remove oil, timing, cooling, or airflow—and the system collapses.

Maintain them, and an engine can run reliably for hundreds of thousands of miles.

Once you understand the systems, engines stop being mysterious.

They become mechanical stories—told one explosion at a time.